CASE SERIES

DH series dry type press briquette machine

DH series dry type press briquette machine

Case Description

DH series dry type press briquette machine

Briquette machine comprises of flowing parts: body frame assembly, roller assembly, hydraulic coupling, speed reduction transmission, complete sets of hydraulic system, automatic control system, dosage screw feeder, forced feeder,automatic lubrication system, bearing temperature detection system, flick gap detection system, etc.

Features

- Dry powder can be directly pressed into balls without any additives.

- The main transmission parts are made of high quality alloy materials.

- Low energy consumption, high efficiency and low failure rate.

- Cyclic operation, continuous production, high pelletizing rate.

- It can control the strength of finished products by adjusting the pressure of rolls.

Applicable materials

Fluorite powder, ceramic clay, iron powder, lime powder, dust removal powder, carbon powder, aluminium powder, ceramic powder, silicon-manganese alloy powder, dolomite powder, alumina powder, manganese ore powder, concentrate powder and other dry powder materials, as well as magnesium oxide, alumina, calcium oxide, laterite nickel ore, desulfurized gypsum, iron oxide scale, sludge, steel slag and so on.

Working principle

Roll press part uses a pair of rollers with a certain gap between them. The two rollers make counter-rotaing at the same speed. One set of the roller axle seats is fixed and the other set slides under the hydraulic pressure. There are a number of arc grooves of the same shape and size aligning regularly on the surface of rollers. Based on different compression ratios, we can adopt the approach of corresponding one roller arc groove to the other(wave trough to wave trough or wave crest to wave crest). The two rollers stay horizontal and parallel. Due to it’s own gravity and the pressure given by the forced feeding machine, powdery materials are consistently and evenly fed into the rollers. As materials are gradually fed into the rollers and rollers are rotating continuously, the space that materials occupy is gradually compressed and the forming pressure reaches its maximum. Pressure gradually reduces afterwards and the compressed granules revert as a result its elasticity and drop from the arc groove because of gravity. Compactor adopts frequency control and its speed depends on the operating conditions of briquette machine and others equipment.

| TECHNICAL PARAMETERS | ||||||||

| Model | DH360 | DH450 | DH650 | DH750 | DH850 | DH1050 | DH1250 | DH1500 |

| Yield(t/h) | 14-4 | 2.5-8 | 3.5-15 | 5-20 | 6-25 | 7-30 | 8-35 | 10-50 |

| Roller diameter(mm) | φ360 | φ450 | φ650 | φ750 | φ850 | φ1050 | φ1250 | φ1500 |

| Roller speed(rpm) | 10-25 | 10-25 | 10-25 | 9-16 | 9-16 | 8.5-14.5 | 6-13 | 6-13 |

| Roller width(mm) | 170-230 | 190-280 | 290-330 | 290-330 | 420 | 450 | 500 | 650 |

| Powder(kw) | 30-37 | 55-75 | 90-110 | 170-200 | 220-250 | 400 | 630 | 400×2 |

| Equipment size(mm) | 2350×2000×2600 | 2600×2200×2900 | 3600×2800×3200 | 4400×3600×3200 | 5000×3800×4100 | 5500×6400×4800 | 7500×6500×5200 | 9700×5600×7700 |

| Total weight(t) | 7 | 10 | 21 | 34 | 42-46 | 76-98 | 100-120 | 120-150 |

| Roller material | Special Alloy Steel | |||||||

| Spherical size | Dpend on Customer's Request | |||||||

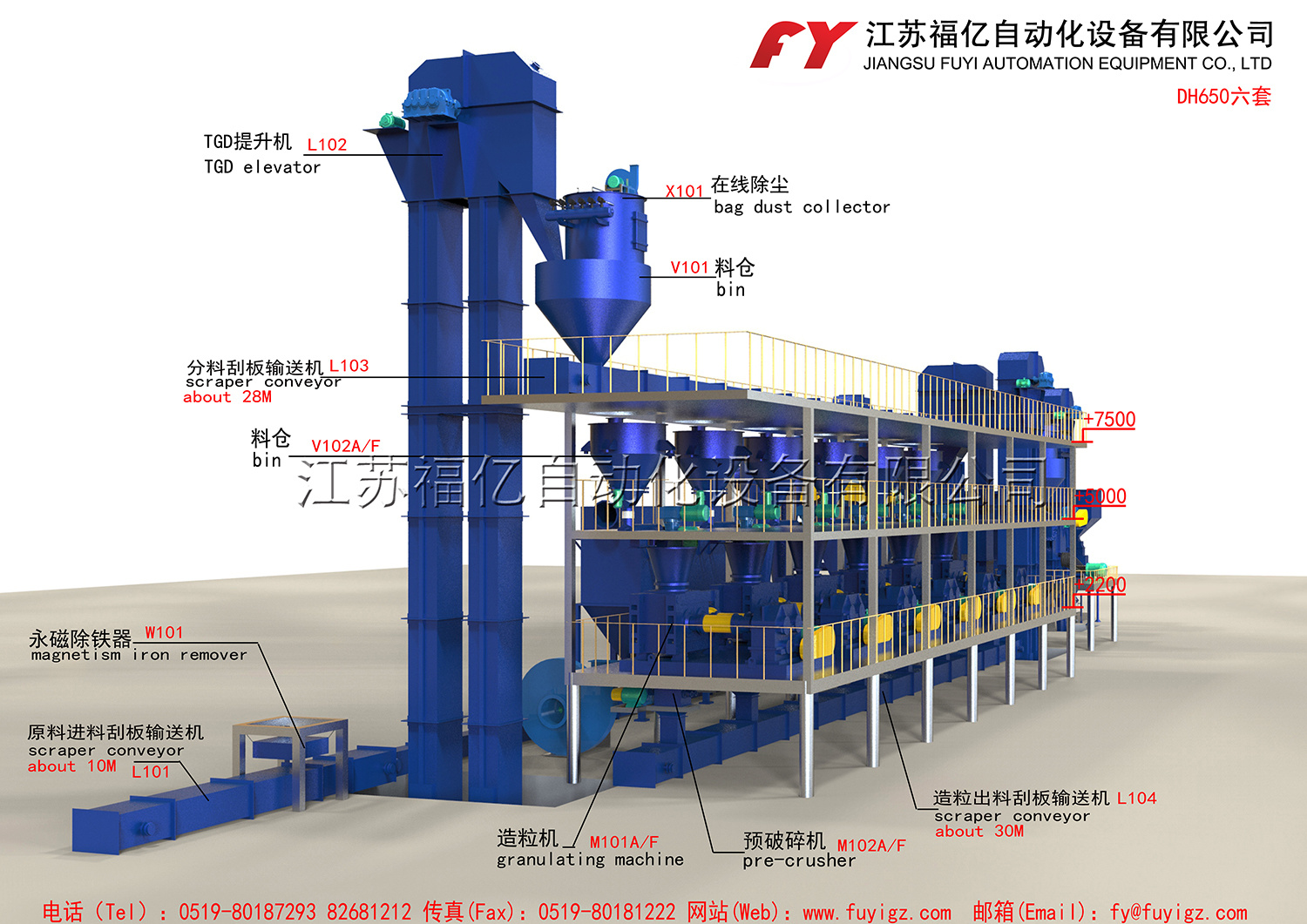

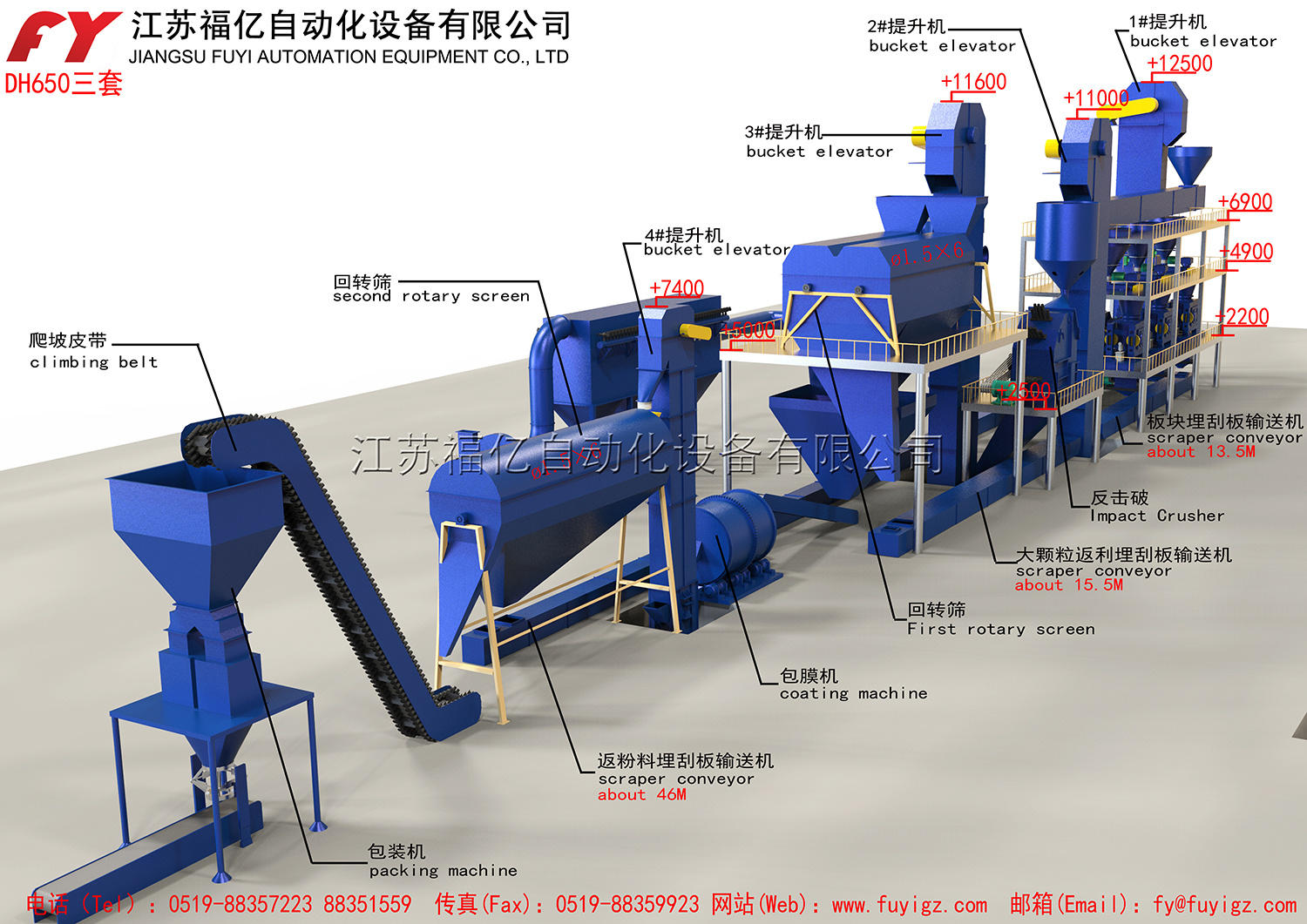

Recommended Cases

Online consultation

Add : Huaxing Road, Jintan Development

Zone, Changzhou City

Tel : 0519-80181222 80187293

Phone :+86-18706143009

+8613196777377

Fax : 0519-80181222

E-mail : fy@fuyigz.com

E-mail : steven@fuyigranulation.com

中文

中文  EN

EN  RU

RU  PT

PT