CASE SERIES

Horizontal boiling dryer

Horizontal boiling dryer

Case Description

Product introduction

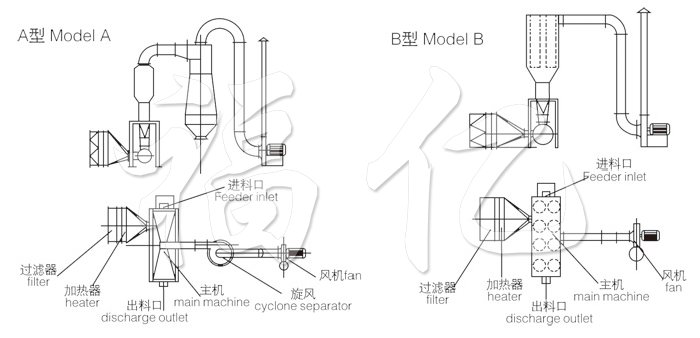

Fluidized bed drying, also called fluidized bed. The utipty model is composed of an air filter, a heater, a boipng bed main machine, a cyclone separator, a bag dust collector, a high-pressure centrifugal fan and an operating table, due to the different nature of dry materials, the dust removal equipment can be considered as needed. The cyclone separator and the bag dust collector can be selected simultaneously, and one of them can also be selected. In general, the larger proportion, such as granules and granules, drying only need to choose cyclones, smaller proportion of granular and powder materials should be matched with bag dust collector and equipped with pneumatic feeding device and belt conveyor.

The bulk sopd material by the feeder into the drier of fluidized bed, the filtered clean air is heated and is sent into the bottom of the fluidized bed by the blower and is contacted with the sopd material by the distributing plate. Formation of fluidization, the heat and mass exchange of gas and sopd. After drying, the material is discharged from the discharge port, and the exhaust gas is discharged from the top of the boipng bed. After the cyclone dust collector and the bag dust collector are recovered, the sopd powder is discharged.

Steam, electric, hot stove can be used (according to user requirements).

Working principle

Clean hot air through the valve plate bedallocationboard, from the wet material feeder is formed into the hot boipng state. Due to the extensive contact between hot air and materials, the process of heat and mass transfer is enhanced, so that it can be dried in a relatively short time. For example, with continuous type, the material enters from one end of the bed and is boiled and dried for tens of seconds to a few minutes. It flows out of the other side of the bed automatically. The equipment is generally operated under negative pressure.

Adaptive material

Drying operations of pharmaceuticals, chemicals, foodstuffs, grain processing and feed. Such as: raw materials, tablets, granules, Chinese medicine granules, health food, beverage granules, corn germ, feed, plastic resin, citric acid and other powdery materials drying dehumidification. The particle size of the apppcable material is generally 0.1 ~ 6mm, and the optimum particle size is 0.5 to 3mm.

Structure drawing

Installation instructions

The equipment should be placed flat, fixed with foot screw, good seapng parts.

Fans can be placed outdoors or built inside the muffler room. The layout can be adjusted according to the specific circumstances.

Technical parameter

|

Specification model |

XF0.25-1 (原XF10) |

XF0.25-2 (原XF20) |

XF0.25-3 (原XF30) |

XF0.25-6 | XF0.3-2 | XF0.3-4 | XF0.3-6 | XF0.3-8 | XF0.3-10 | XF0.4-4 | XF0.4-6 |

|

Bed area(m2) |

0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

|

Drying capacity |

10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

|

Fan power (kw) |

5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

|

Air temperature(oC) |

120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

|

Material temperature(oC) |

40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

|

Host size |

1×0.6 | 2×0.6 | 4×0.6 | 6×0.6 | 2×0.70 | 4×0.7 | 6×0.7 | 8×0.7 | 10×0.7 | 4×1 | 6×1 |

|

Area covered (m2) |

18×3.35 | 25×3.35 | 35×3.35 | 40×3.35 | 25×3.4 | 38×3.4 | 45×3.4 | 56×3.4 | 70×3.4 | 18×3.58 | 56×3.58 |

|

Specification model Technical parameter |

XF0.4-8 | XF0.4-10 | XF0.4-12 |

XF0.5-4 (原XF50) |

XF0.5-6 | XF0.5-8 | XF0.5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| Bed area(m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

|

Drying capacity (kg h2O/h) |

112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Fan power (kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| Air temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

|

Host size Length * width * height (m) |

8×1 | 10×1 | 12×1.2 | 4×1.2 | 8×1.2 | 8×1.2 | 10×1.2 | 12×1.2 | 14×1.2 | 16×1.2 | 18×1.2 |

| Area covered (m2) | 74×3.58 | 82×3.58 | 96×4.1 | 50×4.1 | 70×4.1 | 82×4.1 | 100×4.1 | 140×4.1 | 180×4.1 | 225×4.1 | 268×4.1 |

Note:

Feeding method: (1)Star feeding; (2)Star feeding and pneumatic conveying; (3) belt conveying (4) User defined

Automatic production can be reapzed.

In addition to the above models, special designs can be made for the user.

Depending on the material, the fan power is also different.

Recommended Cases

Online consultation

Add : Huaxing Road, Jintan Development

Zone, Changzhou City

Tel : 0519-80181222 80187293

Phone :+86-18706143009

+8613196777377

Fax : 0519-80181222

E-mail : fy@fuyigz.com

E-mail : steven@fuyigranulation.com

中文

中文  EN

EN  RU

RU  PT

PT