CASE SERIES

GMC series bag type dust collector /Cyclone dust collector

GMC series bag type dust collector /Cyclone dust collector

Case Description

一、GMC series Pulse bag filter

Product overview :

GMC series pulse bag filter is used to separate dust in dust air so as to obtain high purity of air through filter medium, so as to meet the requirements of modern environmental protection. The equipment is widely applied to solid separation and dust recovery in food, food, metallurgy, chemical industry, medicine, building materials and other industries.

Working principle:

After the dust gas is entered by the upper inlet of the ash bucket, the flow of air flows upward and the flow velocity is reduced under the action of the windshield, and some large particle dust is separated and fall into the ash bucket because of the action of the inertia force. The dust gas is filtered and purified through the filter bag, and the dust is hinded to the outer surface of the filter bag. The purified gas is entered into the upper box through the filter mouth and discharged by the outlet. With the increase of dust on the surface of the filter bag, the pressure difference between the inlet and outlet of the precipitator also increases. When the resistance of the dust collector reaches the set value, the control system sends out the ash removal instruction and the ash removal system starts to work. First, the solenoid valve is opened immediately after receiving the signal, so that the compressed air of the upper gas chamber of the small diaphragm is discharged. Due to the change of the force of the small diaphragm, the exhaust passage that is closed by the small diaphragm is opened, the compressed air in the upper gas chamber of the large diaphragm is discharged from the channel, and the force of the large diaphragm is changed, so that the action of large diaphragm will be closed. The output port is opened, the compressed air in the air bag is sprayed into the bag through the output tube and the spray pipe, and the ash is cleaned. When the control signal is stopped, the solenoid valve is closed, the small diaphragm and the large diaphragm are reset successively, and the injection stop is the key component. The service life is the most concerned problem of the user.

Component parts:

Its working principle is to use waterproof and oil repellent to dust filter bag filter dust content in air, and the removal of oil to water sterilized compressed air, pulse electromagnetic valve regularly blowing, dust were collected after being shot down.It mainly includes the following parts:

Cylinder: It consists of three parts Upper cylinder, Medium cylinder and Lower cylinder.

Medium cylinder is the main place for dust collection,which is used to install frame and bag.

Upper cylinder is actually a channel of clean air after filtering, gas storage bag, solenoid valve, nozzle installed here.Lower cylinder is a place to store materials, after hitting the powder is concentrated here.

framework, venturi tube, filter bag:

Compressed air the Scripture's tube after accelerated into the filter bag injection, skeleton is to prevent the bag after the aspiration of the draught fan filter area and reducing the main supporting bag.

injection pipe、electromagnetic valve

Compressed air through the electromagnetic valve timing injection blow, in blowing against venturi nozzle with a plurality of 5mm hole, compressed air here enter venturi tube.

(4)Pulse controller:

It controls the timing of the electromagnetic valve opening and closing, as well as the length of time and the interval of the switch, the two parameters can be adjusted by the knob on the pulse control instrument, in order to achieve the best effect of dust.

Technical parameter:

|

Model |

Filter area(m2) |

Filter bag number |

Filter bag length(m) |

| GMC6 | 4.5 | 6 | 2 |

| GMC9 | 6.8 | 9 | 2 |

| GMC16 | 12.0 | 10 | 2 |

| GMC25 | 18.0 | 25 | 2 |

| GMC36 | 27.0 | 36 | 2 |

| GMC48 | 36.0 | 48 | 2 |

| GMC60 | 45.0 | 60 | 2 |

| GMC72 | 54.0 | 72 | 2 |

| GMC104 | 78.0 | 104 | 2 |

| GMC130 | 98.0 | 130 | 2 |

| GMC160 | 120.0 | 160 | 2 |

| GMC200 | 180.0 | 240 | 2 |

| GMC240 | 180.0 | 240 | 2 |

| GMC300 | 225.0 | 300 | 2 |

| GMC350 | 280 | 350 | 2 |

| GMC400 | 320 | 400 | 2 |

| GMC450 | 360 | 450 | 2 |

| GMC500 | 400 | 500 | 2 |

| GMC600 | 480 | 600 | 2 |

Advantage:

It has high purification efficiency, that is, the efficiency of collecting fine dust can reach more than 99%, and its efficiency ratio is high. It can recover high resistivity dust than the electrostatic precipitator, and it can recover high resistivity dust. Compared with Venturi scrubber, the power consumption is small and the recycled dry particles are convenient for comprehensive utilization. The bag filter is suitable for drying fine particles.

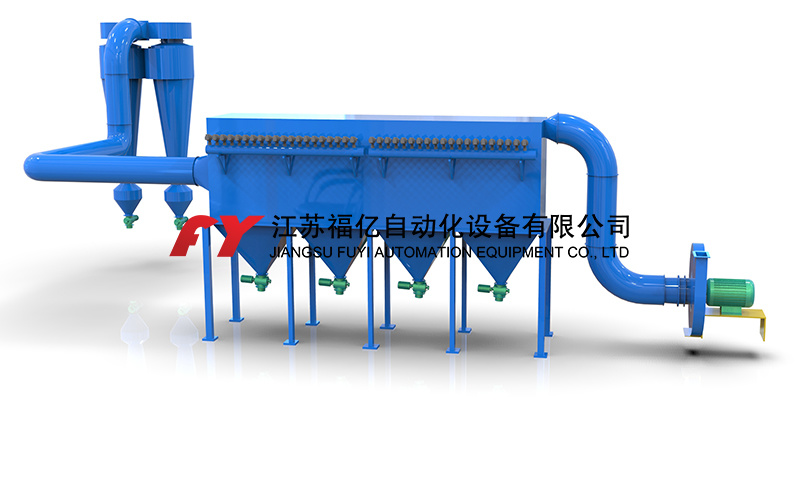

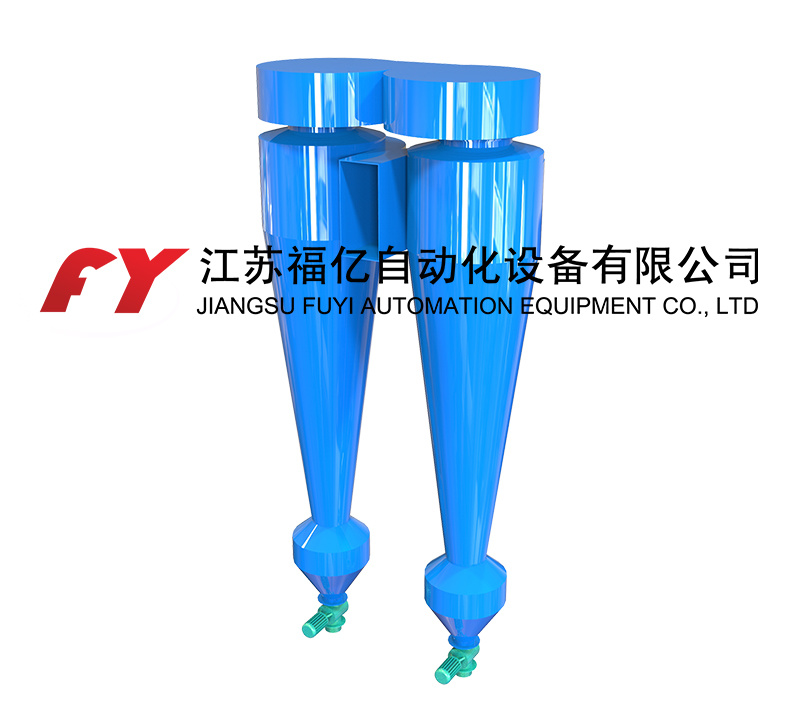

Cyclone dust collector

Working principle:

A dust containing gas is introduced into the dust collector's shell and exhaust pipe from the inlet to form a swirling downward outer swirl. The dust suspended in the external swirl flow moves to the wall under the action of centrifugal force, and is transferred to the lower part of the dust collector with the external swirling flow and discharged by the dust discharge hole. The purified gas forms an ascending internal vortex and is discharged through the exhaust pipe.

Main functions:

The main function of the cyclone separator is to remove the solid particle impurities and droplets carried in the gas as much as possible to achieve the separation of gas and solid liquid so as to ensure the normal operation of the pipeline and equipment.

Application scope:Cyclone cleaner is suitable for cleaning non sticky and non fiber dry dust more than 5-10 microns. It is a kind of purifying equipment with simple structure, convenient operation, high temperature resistance, low cost of equipment and low resistance. The cyclone dust collector is most widely used in the purification equipment.

Applicable industry:

Chemical fertilizer, wood, food, food, feed, leather, chemical, rubber, plastic, grinding, casting, boiler, incinerator, kiln, asphalt mixing, cement, surface treatment, electronics, semiconductor and so on.

Species:

Cyclone separators have various kinds and different classifications. According to the structure type, it can be divided into long cone, circular simplified, diffusion type and by-pass type. According to its combination and installation, it can be divided into internal cyclone separator (installed in reactor or other equipment), external cyclone separator, vertical and horizontal type, and single tube and multi tube cyclone separator.

Advantage:

1. cyclone dust collector has the advantages of simple structure, small size, no special auxiliary equipment, low cost, medium resistance, no moving parts in the device, convenient operation and maintenance and so on.

2. cyclone dust collector is generally used to capture particles above 5-15 microns. The efficiency of dust removal is more than 80%. In recent years, the special cyclone dust collector has been improved. The dust removal efficiency can reach more than 85%.

Installation site:

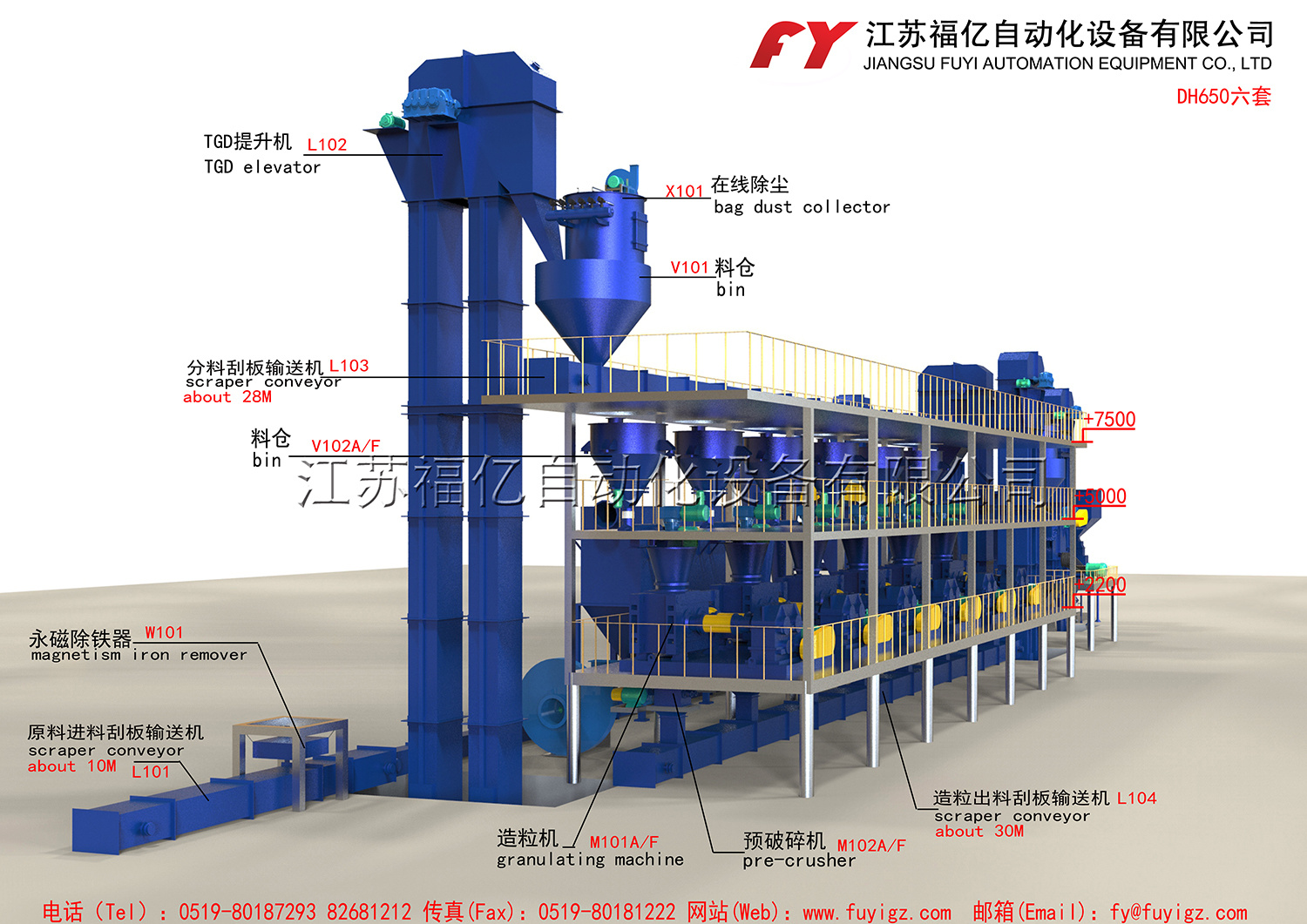

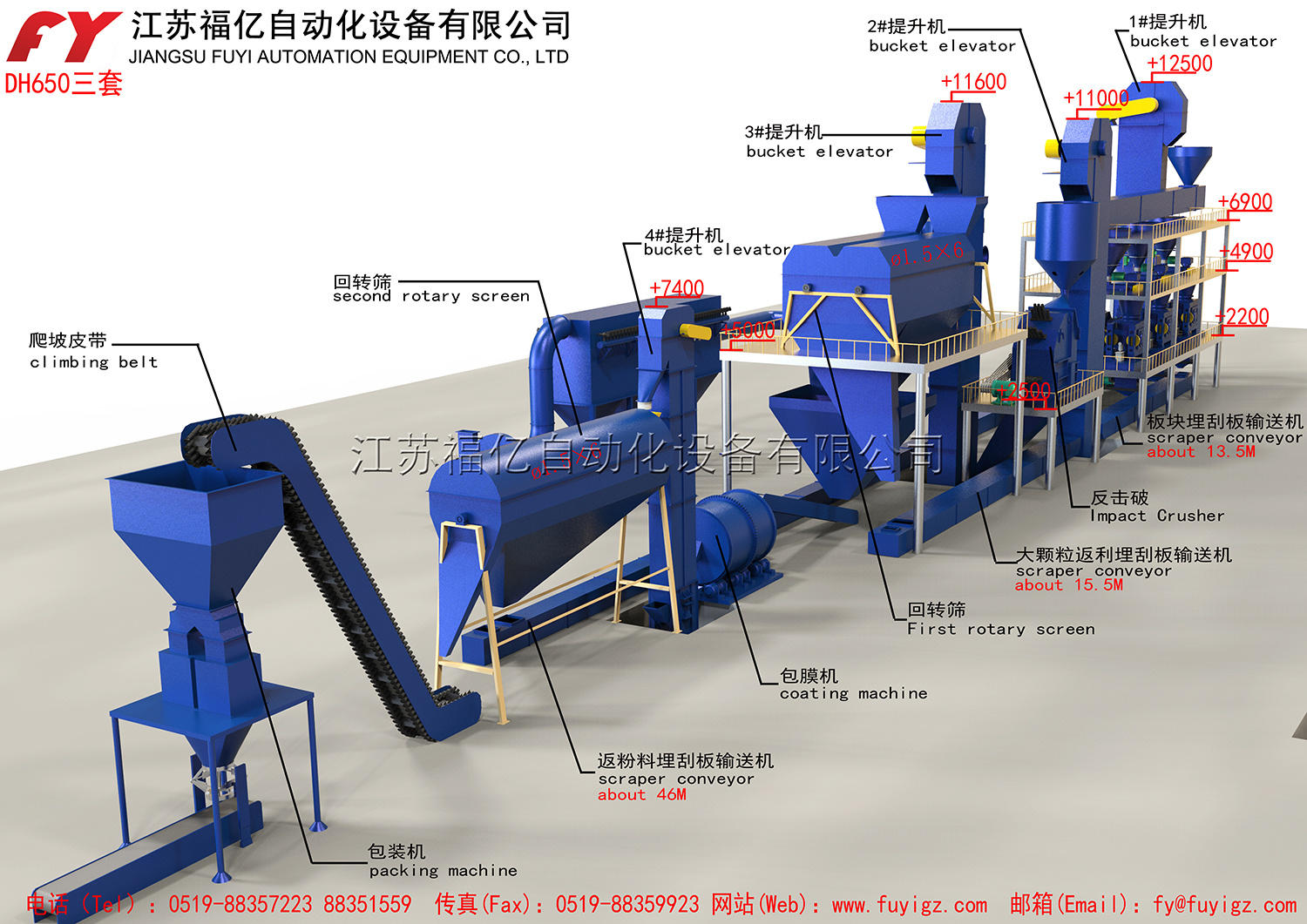

Recommended Cases

Online consultation

Add : Huaxing Road, Jintan Development

Zone, Changzhou City

Tel : 0519-80181222 80187293

Phone :+86-18706143009

+8613196777377

Fax : 0519-80181222

E-mail : fy@fuyigz.com

E-mail : steven@fuyigranulation.com

中文

中文  EN

EN  RU

RU  PT

PT